With well over 400 vacuum forming machines, CNC routers and thermoforming machines in production all over the world, SIBE AUTOMATION has developed the expertise and track record to become an essential part of your next project.

Please take some time to read about our products listed below.

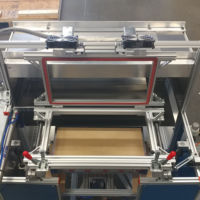

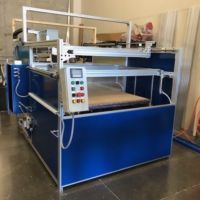

Vacuum Forming Machines

Single Station

We have developed and built numerous production systems for the following industries: aerospace, metal fabrication, medical, packaging, water management, electronics and plastics recycling. With over 25 years experience and well over 300 systems in production around the world, we have developed the expertise and track record to become an essential part of your next project.

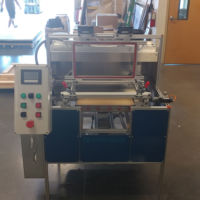

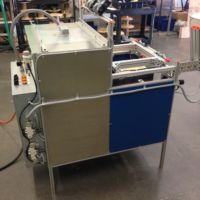

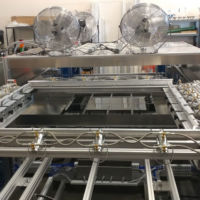

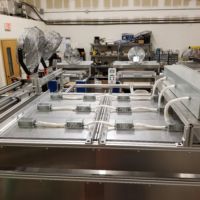

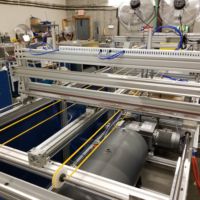

Continuous Roll-fed

We build roll-fed vacuum forming machines in various configurations. Our top of the line is our IL series come equipped with trim press and stacker as well as unwind stand. If you do not need the trim press, we can supply a cut to length slicer that will sheet each index. For the budget-oriented shop, we offer the series HIL of vacuum forming machines. These machines will form advance the material automatically and a slicer will sheet each index.

Routers

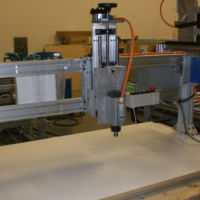

3 Axis CNC Routers

Our CNC routers are used in sign and graphics fabrication 3-Dimensional (3D) machining (sign, plastics, wood, molds, etc.) Cabinetmaking furniture, general woodworking manufacturing store fixture, display manufacturing sheet plastic fabrication solid surface machining non-ferrous metal machining (aluminum, brass, copper, zinc) composite machining (graphite, phenolic, Kevlar, etc.)

All our routers are designed and built based on our knowledge of proper machining practices and machine building procedures

We build these 3 axis CNC routers in four different working envelope configurations:

- 60″ x 120″ x 10″ travel Z-axis

- 48″ x 96″ x 10″ travel Z-axis

- 48″ x 48″ x 10″ travel Z-axis

- 36″ x 36″ x 8″ travel Z-axis

- Custom configurations available

Each machine features a high strength custom engineered aluminum construction designed to ensure rigidity and accuracy.

All axis is composed of linear ball bearings mounted on precision machined plates and ride on hardened shafts.

All our router are shipped fully assembled, all software preloaded, no need to buy additional components, uncrate, plug and work (read the manuals first)

Each machine undergoes a rigorous real-life test prior to shipping. These are rugged, precise machines designed to operate in an industrial facility .easy to operate and service with full cad cam software.

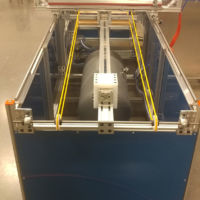

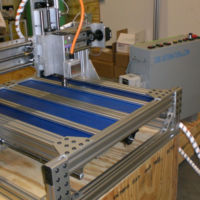

Overhead Routers

Great machine to trim vacuum formed parts.

The pneumatically driven head retracts 6″ away from the part without losing the depth of cut that is controlled separately.

The frame of the machine is built of heavy-duty structural aluminum extrusion.

The machine is mounted on a base with a working envelope of 48″ x 48″ and the Z-axis will travel 10″.

All linear bearings ride on hardened shafts and are mounted on precision machined plates.

The Z axis is driven by a trapezoidal lead screw.

FIMEC variable speed 1.34 HP SPINDLE MOTOR 0 TO 24000 RPM (speed adjustable on the fly). Driven by an ATC variable speed drive, allowing you to adjust it to best match it to different materials

We provide with each machine a convenient operator pendant.

Each machine is supplied with 3 sizes of R200 collets: ¼”, 3/8″ and ½”, also included are spindle and collets wrenches.

Each machine undergoes a rigorous real-life test.

Machine requires 220 volts, 3 phase, 10 amps, other voltages available

This is built to order machines, current lead time is 3 weeks.

Each one of our machines is covered by a 12-month limited warranty and is backed by a 24/7 technical support.

Point-to-point Routers

For those applications that do not require a full CNC router, we offer our point to point routers.

This machine does an outstanding job slotting, pocketing or drilling items like aluminum extrusions or drilling multiple holes on flat surfaces on all nonferrous materials.

We can build this machine in any X Y Z size configuration

1.34 Hp Ekstrom Spindle Motor At 24000 Rpm Max Controlled By An Atc Frequency Drive We Furnish It With Three Collets 1/4″, 3/8″ And 1/2″

Powerful Nema 34 Stepper Motors

Trapezoidal lead screws, we usually maintain tolerances of +- 0.003″

Programming Is Plain English Via any computer with a serial port.

Power Is 220 Volts 3 phase, other voltages available

Custom Routers

Router lathe.

This is a great, clever machine design. It will process any nonmetallic material that requires routing work on its faces with a turning constraint such as columns and pillars.

It will handle pieces up to 24″ diameter and 8 feet long.

This is a 4 axis machine, all Servo driven.

4.7 HP Fimec spindle with AC tech frequency drive max 18000 RPM, max collet size is 3/4″.

Programming thru regular G code or upload tool paths from programs such as Mastercam.

One end acts as a live center.

In order to help locate pieces, the machine comes equipped with a hydraulic lift.

Other Products

Drying Ovens

Our factory floor proven drying ovens are custom built to your specific needs. All aluminum framing construction, properly insulated and double access doors. We can supply our ovens with sheet carts. Hot circulating air is provided by a belt driven New York blower and finned heaters. Our ovens will reach 300 degrees Fahrenheit, polycarbonate usually dries at 180 degrees and abs at 140 degrees Fahrenheit. Each oven incorporates solid state relays to control heaters and an automation direct plc to provide accurate control of the system.

Features:

- All aluminum framing construction

- Properly insulated

- Double access doors

- Belt-driven New York Blower

- Reaches 300 degrees Fahrenheit

- Easy to use touch screen operator interface, to see detailed operation instructions please go to our manuals section

- All our ovens are covered by 1-year limited warranty.

Another factory-floor-proven SIBE Automation system.

We build them small and we build them large!

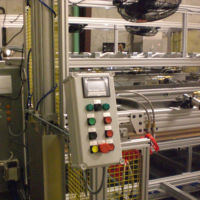

Control Panels

Our control systems are specifically designed to provide precise control to the heaters of your thermoforming machine while providing energy management. We build control systems with as little as 4 zones and up to 120 zones. Control of each zone is provided by percentage timers run by an automation direct PLC. The PLC also provides for a soft start sequence reducing power usage by about 30%. The input of percentage to each heater is done via an included DV-1000 operator interface. We also build panels where the control is provided by thermocouple input (closed-loop system). Each zone is connected to a Carlo Gavazzi solid state relay. Systems are shipped ready to run, just connect your power to the power distribution block included. Great for retrofits of older thermoforming machines. All our systems are covered by a 12-month warranty.

Features:

- Designed to provide precise control

- Energy management

- Control of each zone is provided by percentage timers or thermocouple input

- Each zone is connected to a Carlo Gavazzi solid state relay

- Systems are shipped ready to run

- Great for retrofits of older thermoforming machines

Another field proven system from SIBE Automation.

We also build complex control systems incorporating the latest technology on servo motors and drives.

We can provide turnkey solutions at a reasonable cost and prompt delivery.

Roller Die Cutters

Creating leading edge roller press die cutters for all industries.

- Machine will cut 27″ wide material (other configuration available on request)

- Both top and bottom rollers have a diameter of 4″

- Maximum height of cut is 8″

- Rigid 4 post construction, post are 1.250″ in diameter

- All three plates are steel 1″ thick

- Bottom roller is driven by a 1 HP single phase motor attached to a gearbox

- Dual roller driven machine as an option

- Cutting speed is 70 ft. per minute

- All functions of the machine are controlled by a PLC

- Operation from both ends

- Ideal machine to die cut materials such as foams, rubber, leather, plastic sheets, skin packaging, blisters

- Single point adjustment of rollers gap

- 110 VAC or 220-240 VAC, single phase

Vacuum Systems

This is a complete vacuum system ready to plug and work.

All wiring ( motor starter, circuit protectors, etc) and plumbing already done. Built from quality filed proven components.

We only use Becker vacuum pumps.

We build these units in three different sizes:

- 24 gallons vacuum tank – 0.93 HP pump

- 50 gallons vacuum tank – 1.3 HP pump

- 100 gallons vacuum tank – 3 HP pump

High flow, 1″ vacuum valve

Vacuum gauge

Remote pendant to activate vacuum valve

All mounted in an attractive aluminum stand

Operates in single or three phase power supply, when ordering specify voltage needed

Great for those building their own machines or for those cases where you need an additional source of vacuum

All our systems are covered by a 12-month limited warranty

Not for use with compressed air or other gases or liquids under pressure

We have a complete stock of vacuum pumps